Introduction to Heavy Duty Truck Ramps

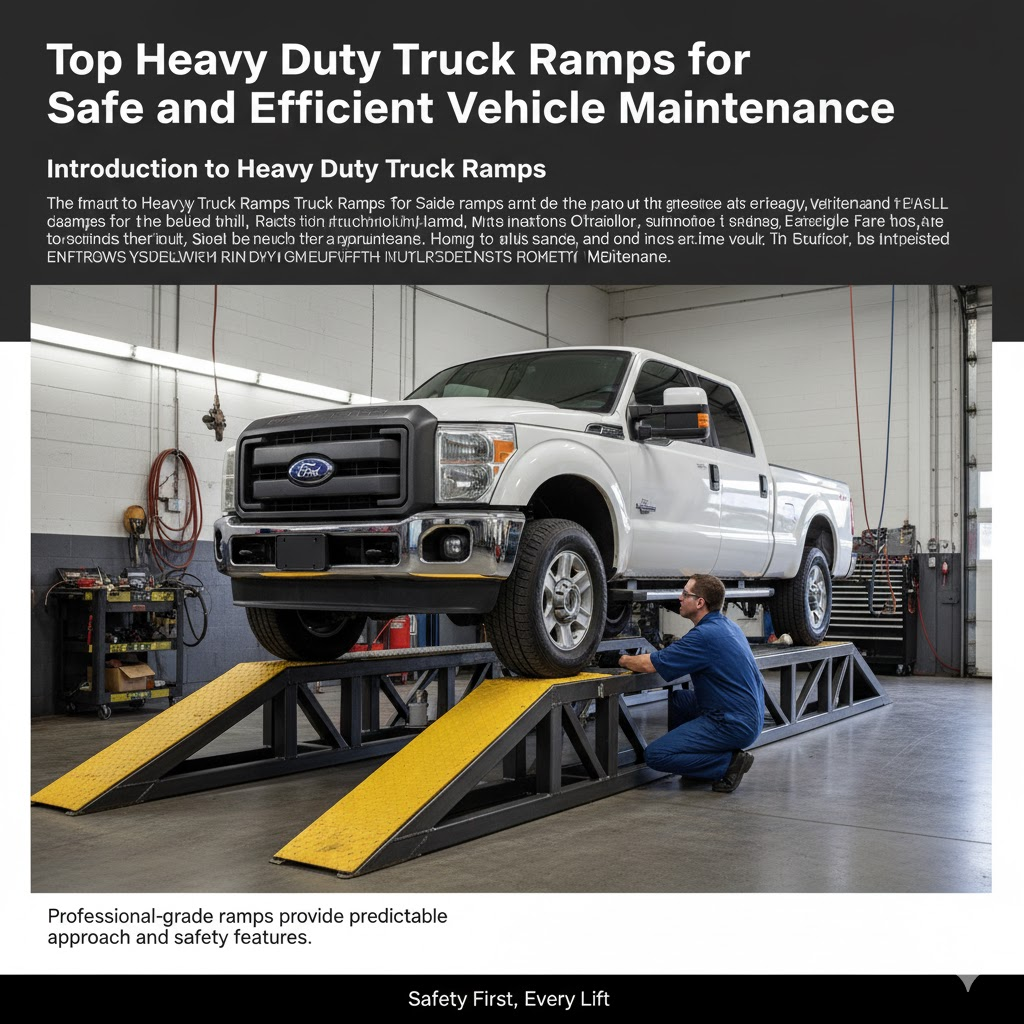

When you’re working under 6,000–40,000 lb of steel, the difference between a calm service day and a scary one is the quality of your truck ramps. The right heavy-duty ramps give you predictable approach, real ramp safety (traction, anchoring, and stop geometry), and quick mobility around the shop. Unlike ad-hoc cribbing, purpose-built garage ramps are engineered with known rated load limits, non slip surface treatments, and load paths that respect tires and frame. In this guide, we’ll compare proven options, highlight the safety features that matter, and help you choose a ramp that fits your vehicles, your floor plan, and your tasks—from fluid changes to brake and steering work.

Key Features to Consider

Weight Capacity

Start with the truck’s gross vehicle weight and, more importantly, front and rear axle weights (GAWR). Ramps are typically rated per pair or per ramp—verify which. A “20-ton pair” means 40,000 lb spread across both ramps; a “10-ton per ramp” system gives the same total but clarifies per-wheel loading. For safety margin, spec at least 1.5× your measured axle weight. If you service duallies or medium-duty rigs, treat heavy equipment ramps with the same caution you give a lift: confirm vehicle lifting angles, tire width, and contact patch.

Material and Durability

- Steel ramps: Highest stiffness and long life; look for welded gussets, reinforced hinges, and powder coated ramps or galvanized option for a corrosion resistant coating.

- Aluminum ramps: Lighter portable ramps and portable ramp systems with excellent moveability; verify ribbing, cross-members, and high traction surface to avoid flex and slip.

Safety Features

- Anti slip grip / high-traction deck and a non slip surface at the lip.

- Positive wheel ramp guards/stops sized for your tire diameter.

- Ramp anchor points or base mats to prevent shuffle on smooth concrete.

- Wheel chocks kit for the axle that stays on the floor.

- Clear ramp angle guidance/vehicle lift height so you know what clearance you’ll gain.

- Compliance (e.g., ASME/PASE for shop gear), where applicable.

Top Heavy Duty Truck Ramps

We prioritized clear ratings, service-friendly design, mobility around the bay, and weather/floor resilience. Confirm model numbers and specs with the manufacturer—capacities and options vary by revision.

Rampzilla by Warren Steel

Mobile service ramps designed for HD pickups and work trucks, with a published spec of up to 10 tons per ramp (20 tons per pair). The big wins are the wide tread, tow-style mobility, and a stop profile that keeps tires centered as you climb. Excellent for service bay ramps that you roll between lanes without a forklift.

Best for: Fleet shops and mobile truck servicing where you want a stout, rollable platform.

Notable features: Wide deck with anti slip grip, tow handle/wheels, options for different lip height options.

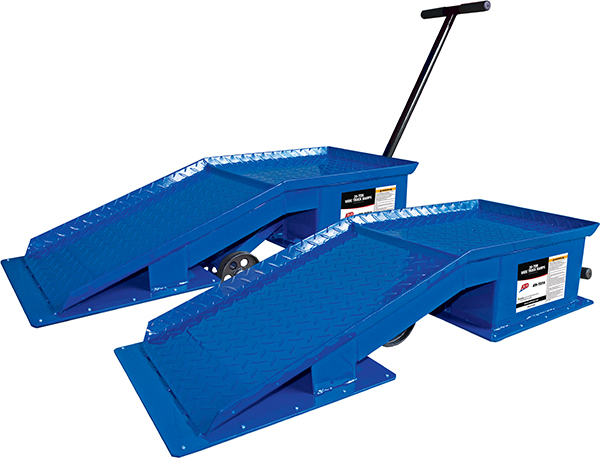

ATD 20-Ton Wide Truck Ramps (ATD-7321A)

Heavy steel construction, wide footprint, and practical shop ergonomics (long retractable T-handle and large wheels). ATD lists 20-ton capacity (pair), non-skid matting under the base, and states compliance with ASME PASE 2019—the standard many shops require for garage equipment. Sold and used in pairs.

Best for: Fixed bays that need reliable workshop tools with shop-floor mobility.

Notable features: Wide base, ramp safety devices (matting), powder coated steel.

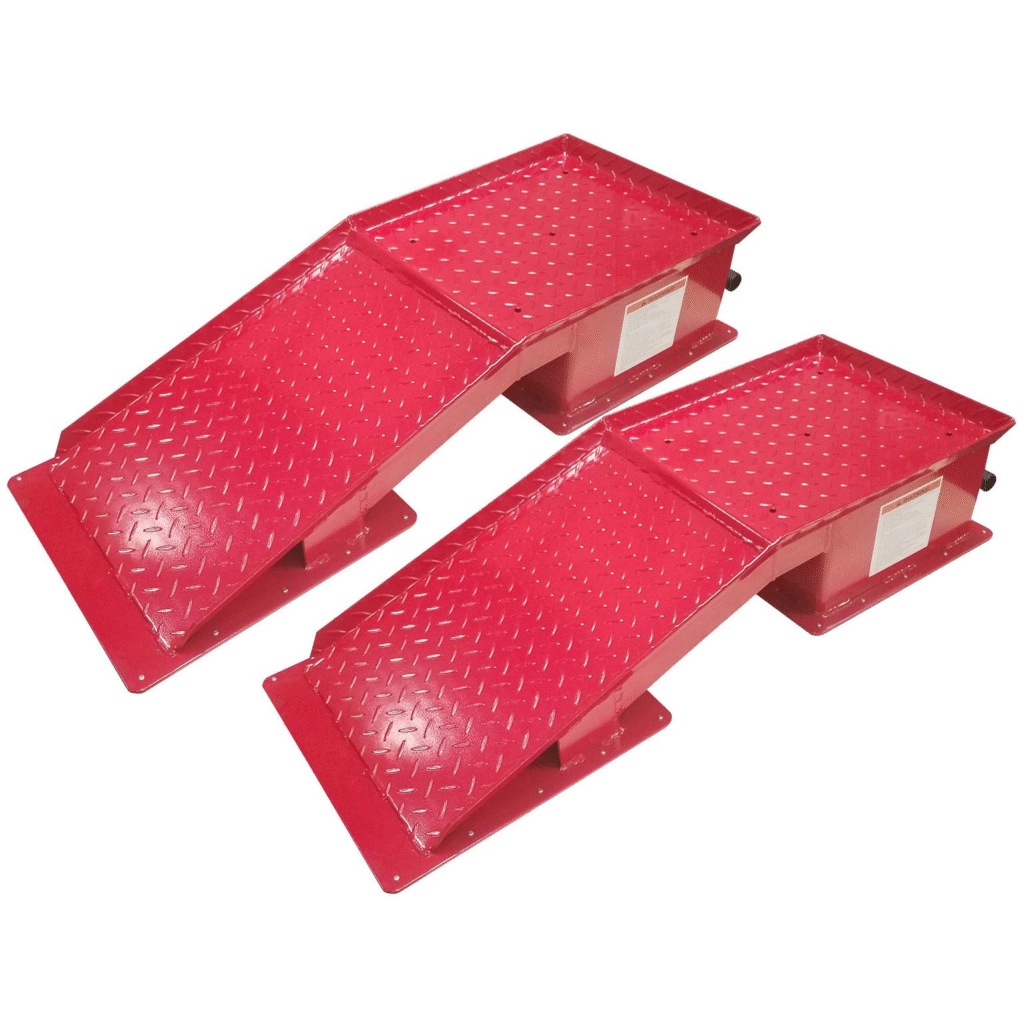

Redline 20-Ton Heavy-Duty Mobile Truck Ramps

A portable, diamond-plated steel set marketed at 20 tons per pair, with extendable T-handles and wheels so one tech can reposition them. A strong pick when you need mobile truck ramps that still feel like shop fixtures.

Best for: General vehicle servicing on three-quarter and one-ton pickups; occasional medium-duty.

Notable features: Textured deck, mobile base, clear rated load limits labeling.

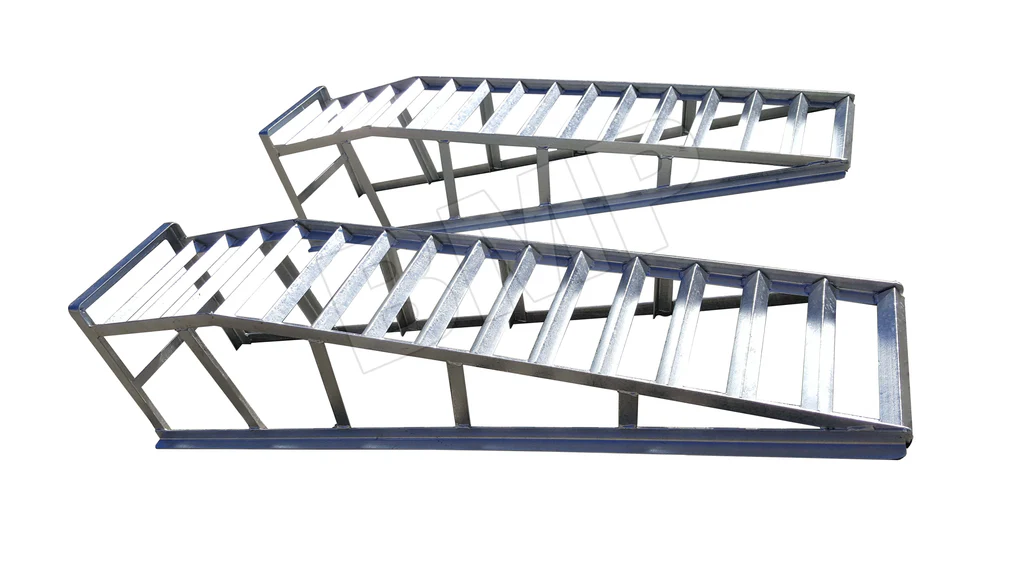

LongRamps Heavy-Duty Loading Ramps

These are loading ramps—purpose-built aluminum vehicle loading ramps for powersports, bikes, and light vehicles—not stand-under service ramps. They shine when you need to move equipment into a truck or trailer with low weight and excellent ramp portability/foldable ramps/extendable ramps options. Use for equipment handling and loading dock ramps scenarios; for under-vehicle work, stick to service ramps rated for static support.

Best for: Loading/hauling tasks where light weight matters and you’re not crawling underneath.

Notable features: Aluminum ramps, modular lengths, high traction surface.

Heavy-Duty Galvanized Steel Ramps by Best Metal Products Corp.

Hot-dipped galvanized steel ramps designed for trucks, tractors, and shop vehicle maintenance—a great pick where humidity or winter salts attack paint. The brand’s lineup includes service ramps and DIY kits; look for “heavy duty … truck tractor service ramps” SKUs and match size to your tire width.

Best for: Coastal/snowbelt shops needing a galvanized option that shrugs off corrosion.

Notable features: Zinc coating, modular parts (modular ramp system), USA-made options.

Snapshot Comparison (typical attributes; confirm exact model data)

| Model | Material | Capacity (pair) | Mobility | Surface | Coating | Stand-Under Service? | Notes |

| Rampzilla (Warren Steel) | Steel | 20-ton (10/ram p) | Tow handle + wheels | High traction plate | Painted / coated | Yes | Wide deck, multiple lip heights. |

| ATD-7321A 20-Ton | Steel | 20-ton | Long T-handle + wheels | Non-skid base & deck | Powder coated | Yes | ASME PASE 2019 noted. |

| Redline 20-Ton Mobile | Steel | 20-ton | Extendable T-handle + wheels | Diamond plate | Painted | Yes | Portable pair for shop moves. |

| LongRamps (Loading) | Aluminum | Varies (loading) | Carry/roll | High traction | Bare/anon. | No | For vehicle loading ramps, not service. |

| Best Metal Products (Galv.) | Steel | Varies by SKU | Fixed/movable | Textured | Hot-dipped galvanized | Yes (service SKUs) | Corrosion-hardy kits/ramps. |

Service vs. Loading: “Loading” ramps move equipment onto beds/docks; “service” ramps are designed to support a stationary vehicle while you work below. Never substitute one for the other.

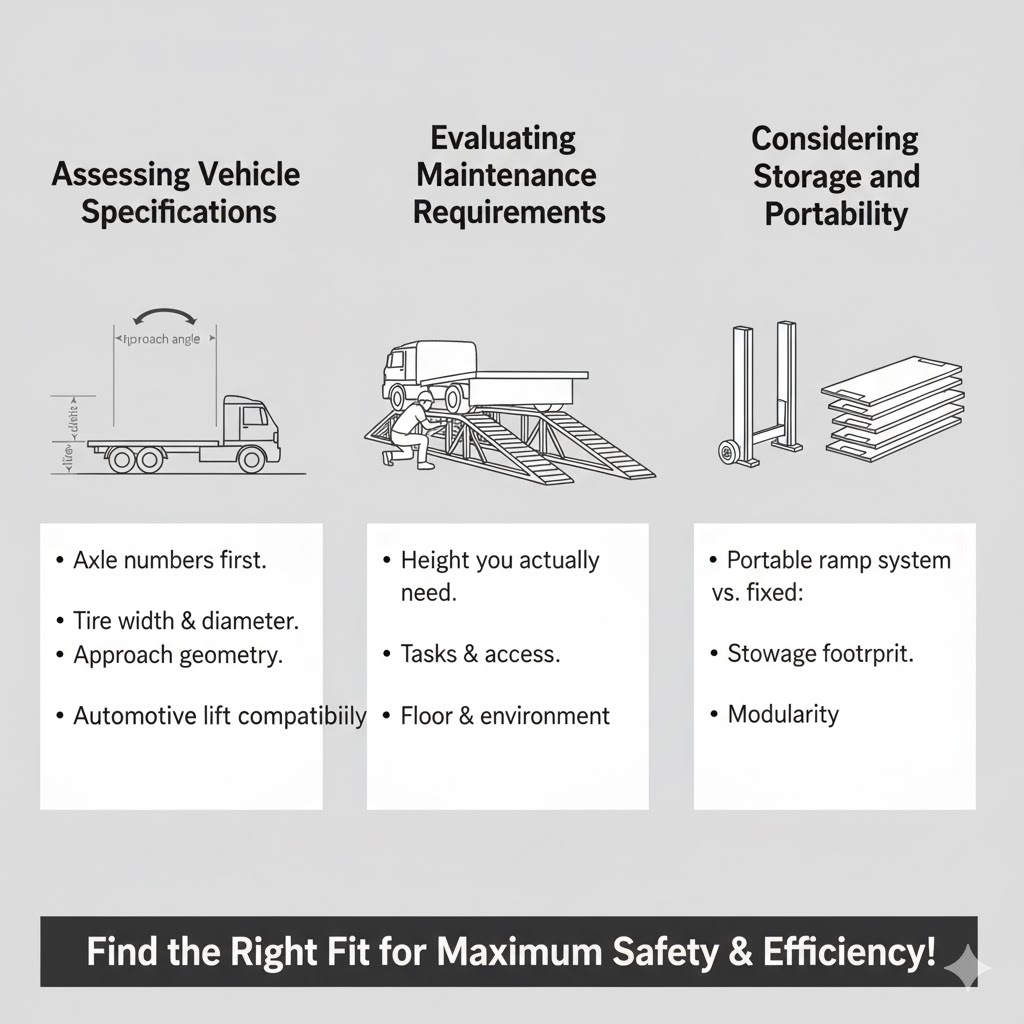

How to Choose the Right Ramp for Your Needs

Assessing Vehicle Specifications

- Axle numbers first. Use CAT/scale tickets or in-shop scales to know real front/rear weights.

- Tire width & diameter. Choose deck width and wheel ramp guards that fully cradle the tread.

- Approach geometry. Low air dams or long wheelbases need longer ramp incline for bumper clearance.

- Automotive lift compatibility. If you use a four-post, “run-up” workshop ramp solutions can double as approach aids.

Evaluating Maintenance Requirements

- Height you actually need. A 6–10” vehicle lift height gain is enough for many fluid/brake jobs; alignment or exhaust may call for more.

- Tasks & access. Steering/suspension work benefits from a ramp with flat top sections for stands or turn plates (ramp angle guidance matters here).

- Floor & environment. Smooth epoxy? Favor bases with anti slip grip or add base mats. Salt belt? Pick the galvanized option.

Considering Storage and Portability

- Portable ramp system vs. fixed: wheel-equipped ramps roll between bays; fixed service bay ramps save time if you repeat the same work daily.

- Stowage footprint. Check handle length, wheel size, and stacking; verify that ramp installation kit hardware stores on-board.

- Modularity. A modular ramp system lets you swap heights (lip height options) or add wheel chocks kit and tire protection pads.

Practical Selection Flow (2 minutes)

- List your heaviest axle (fully fueled, with equipment).

- Multiply by 1.5× → minimum rated load limits for the pair.

- Match deck width ≥ tire section width, with stop height ≥ 30% of tire diameter.

- Pick material (steel for stiffness/long life; aluminum for lighter handling).

- Choose mobility (wheels/handles) and coating (powder coat vs. hot-dip).

- Verify safety features: wheel ramp guards, base traction, ramp anchor points, chock strategy.

- Check automotive lift compatibility or turn-plate use if needed.

Safety & Setup (shop basics that pay you back)

- Park on level ground, chock the opposite axle, and approach in low gear.

- Keep a dedicated wheel chocks kit at every bay; habit beats memory.

- Confirm contact—tire centered on the deck; stops fully engaged.

- For long-term work, add rated stands at the frame even when on ramps.

- Rinse road salts and grit; they act like ball bearings under ramp bases.

Extra Reference Tables

Approach & Height Table (rule-of-thumb)

| Ramp Rise | Typical Use | Notes |

| 6–8 in | Oil/filter, visual inspection | Fast setup, good for low spoilers |

| 10–12 in | Brakes, steering, under-tray | More arm room; watch approach angle |

| 14–16 in | Exhaust, deep inspection | Consider adjustable incline or longer approach sections |

Feature Checklist (tick what you need)

- Safety features: wheel stops, anti slip grip, anchor/base mat, side rails.

- Durability: steel gussets, reinforced hinges, corrosion resistant coating.

- Usability: wheels/handles, tow eyes, foldable ramps (for loading types).

- Fit: tire width, stop height, lip height options, ramp incline.

- Environment: galvanized option for salt, sealed bearings on wheels.

- Extras: ramp safety devices, tire protection pads, trays for fluids.

Final Thoughts on Selecting Heavy Duty Truck Ramps

Great workshop tools do three things: protect people, protect equipment, and save time. For truck maintenance and vehicle repair, choose heavy duty vehicle ramps that are honestly rated, easy to position, and built for your climate and floor. If you’re a mobile tech, favor wheeled, coated steel ramps with wide decks; if you’re in a coastal shop, that galvanized option will pay for itself in a year. For loading equipment (not stand-under service), lightweight aluminum ramps keep you fast and safe on the move.

Pick once, use for years—and never compromise on chocks, traction, or rating labels. Your back (and your insurance auditor) will thank you.

Leave a Reply