Introduction to Wheel Offset

Open any fitment forum and you’ll see the same question: “Will these fit without rubbing?” That answer starts with wheel offset—the distance between the wheel’s hub-mounting pad and its centerline. A clear grasp of offset, backspacing, and rim width is what turns guesswork into predictable wheel fitment. In this guide we’ll unpack how 12 offset wheels behave on real trucks, why a few millimeters change wheel positioning, and how to read the numbers like a pro. You’ll also get a practical wheel offset guide for handling, clearance, and the small geometry quirks that influence ride feel and tire life.

Working definitions (fast):

- Wheel offset definition: distance (mm) from the wheel’s centerline to the mounting face.

- Positive offset: mounting pad sits toward the wheel’s outside face; the wheel tucks inward.

- Negative offset: mounting pad sits toward the wheel’s inside face; the wheel pushes outward.

- Backspacing: distance (inches) from the wheel’s mounting pad to the back edge of the rim.

- Rim width: labeled in inches (bead-seat to bead-seat). Overall width is ~rim width + 1”.

What Does a 12 Offset Mean?

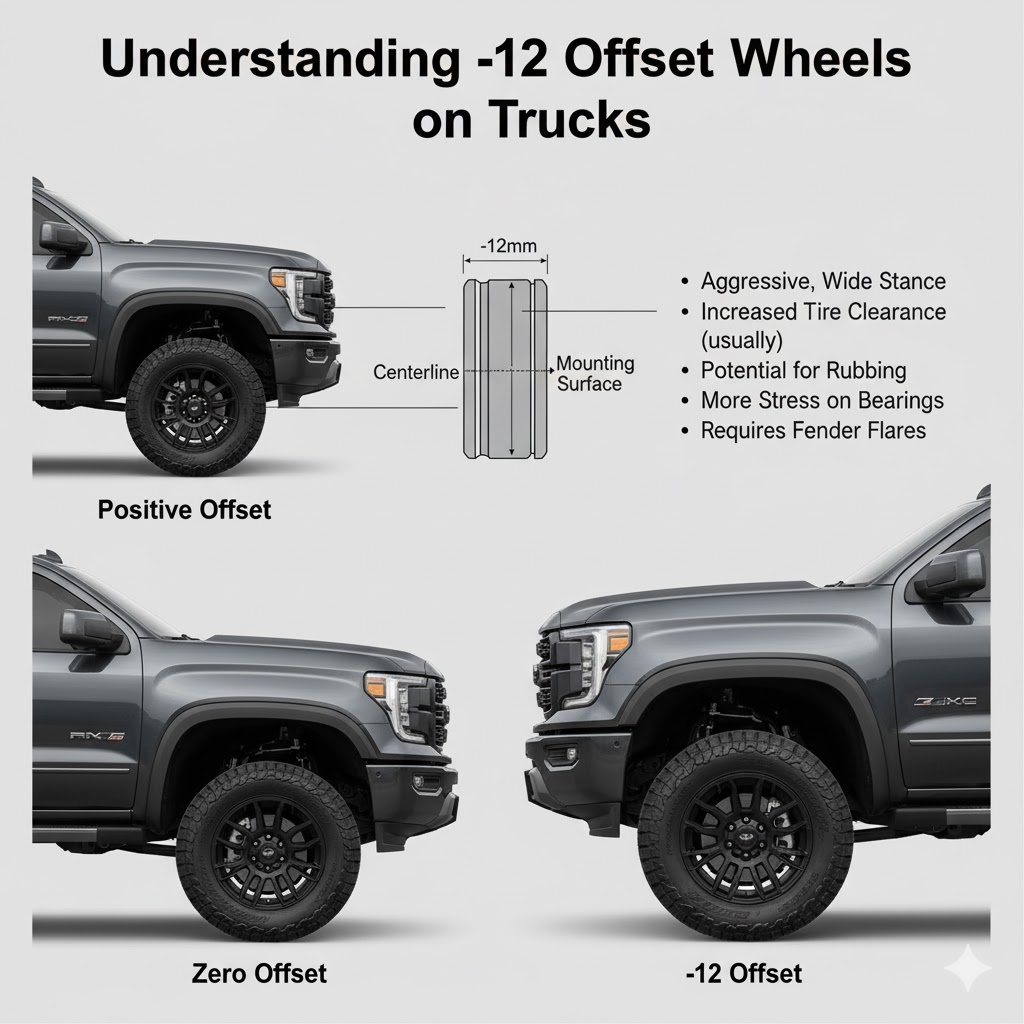

A +12 mm offset moves the mounting pad 12 millimeters outward from the wheel’s centerline. On a typical 8.5” rim, that creates a mild “tuck”—more conservative than +25 and far tamer than −12. A −12 mm would do the opposite, pushing the tire outward for a broader track and more fender exposure.

Positive vs. Negative Offset

- Positive offset (e.g., +12): the wheel sits farther inboard. This usually improves wheel well clearance at the fender lip but tightens inner tire clearance near control arms and sway bars.

- Negative offset (e.g., −12): the wheel pushes outboard, increasing track width and “poke.” That can amplify aggressive stance, but risks fender clearance issues and added spray.

Rule of thumb: every 10–12 mm of offset change shifts the tire about 10–12 mm laterally. It also nudges scrub radius, which subtly affects steering effort and on-center feel.

Impact on Wheel Positioning

Offset interacts with rim width and backspacing. Use this quick wheel offset calculation:

Backspacing (in) ≈ (Rim width + 1) / 2 + (Offset_mm ÷ 25.4)

Example (8.5” rim, +12 mm):

Backspacing ≈ (8.5 + 1)/2 + (12/25.4) ≈ 4.75 + 0.47 ≈ 5.22”.

Move to −12 mm and backspacing drops to ≈ 4.28”, pushing the wheel outward ~24 mm overall.

This math is the backbone of any solid wheel offset chart or offset calculator you’ll find; it’s how you predict brake clearance, caliper clearance, and whether the spokes foul your hub caps or steering knuckle.

Effects on Truck Performance

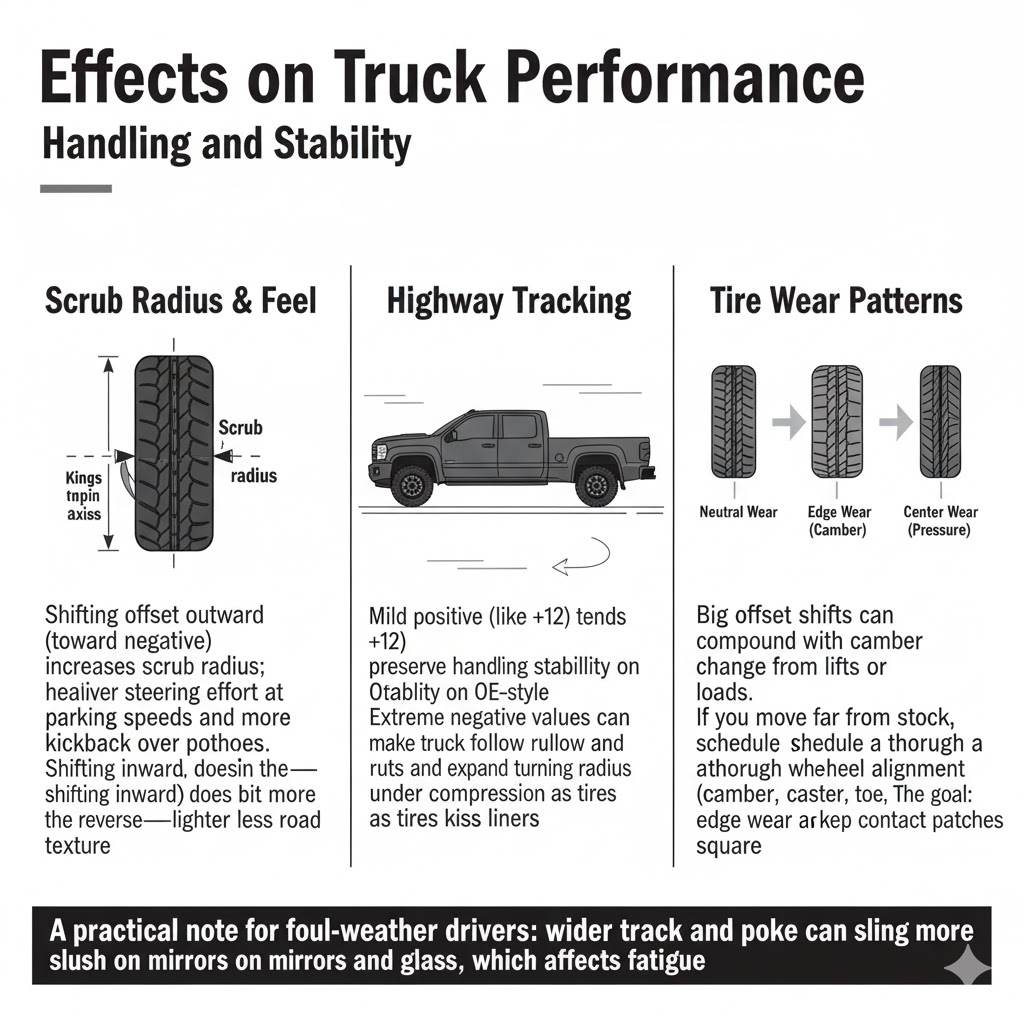

Handling and Stability

Offset tweaks the suspension geometry your truck was designed around:

- Scrub radius & feel: Shifting offset outward (toward negative) increases scrub radius; expect heavier steering effort at parking speeds and more kickback over potholes. Shifting inward (more positive) does the reverse—lighter feel, a bit less road texture.

- Highway tracking: Mild positive (like +12) tends to preserve handling stability on OE-style suspensions. Extreme negative values can make the truck follow ruts and expand turning radius under compression as tires kiss liners.

- Tire wear patterns: Big offset shifts can compound with camber change from lifts or loads. If you move far from stock, schedule a thorough wheel alignment (camber, caster, toe). The goal: neutralize edge wear and keep contact patches square.

A practical note for foul-weather drivers: wider track and poke can sling more slush and grit on mirrors and glass, which affects fatigue.

Clearance and Fitment

Wheel clearance is two battles: inside and outside.

- Inside (backside): Caliper clearance, knuckle clearance, and leaf/coil proximity. More backspacing (from higher positive offset) risks contact under braking and full-lock compression. Check with a straightedge across the hub: you want a few millimeters of daylight between spoke barrels and calipers.

- Outside (fender side): Fender clearance, liners, and mudflaps. Negative offset pushes outward; add steering and bump travel, and fender rub shows up at the liner seam.

- Up & down: Don’t forget ride height effect. Compress the suspension (ramps or jack under the lower arm) and sweep steering lock—fitment that looks fine at static height can rub on the first driveway dip.

If you run aftermarket wheels with deep concavity, confirm hub bore size, center bore alignment, and lug pattern. Wobble or vibration is often a hub-centric mismatch, not a balance issue. Also verify stud length and center cap fitment; short studs plus thick wheels or wheel spacer effects can compromise thread engagement and load rating impact on the hardware.

Visual Impact on Appearance

Aggressive Stance

Offset is the cleanest lever for wheel appearance without changing tires. A shift from +20 to +12 subtly widens track and “flushes” the wheel with the fender—tasteful aggressive stance without mud-slinging poke. Jump to −12 and you’re advertising every groove in the road (and every rock toward your paint). On off-road vehicles, jeeps, and certain SUVs, negative offset complements wide knobbies and beadlocks—but it’s still a geometry trade.

Wheel Well Clearance

Think of the arch as a moving shell around a moving tire. You’re balancing wheel arch fill (looks) against wheel well clearance (function). Taller sidewalls add bulge; wider rims stretch the tire; both change where shoulder hits liner. A mild +12 typically maintains liner clearance while improving flushness on many half-tons—if the wheel sizing and tire width are sensible for the body.

Considerations Before Upgrading

Vehicle Compatibility

Start with what the platform wants. OE engineers pick offsets to protect bearings, joints, and sheet metal. Your job is to deviate responsibly.

- Wheel offset for trucks: half-ton pickups usually live in the +18 to +44 space from the factory; +12 is a modest nudge.

- Wheel offset for SUVs: many mid-size SUVs are closer to +35–+55—dropping to +12 may be too aggressive without liner trimming.

- Wheel offset for jeeps: solid-axle rigs tolerate more negative offset thanks to beefy knuckles, but steering scrub and fender flare laws still apply.

- Wheel offset for vehicles (general): unibody crossovers skew high positive; verify arm clearance before chasing stance.

Confirm vehicle compatibility by measuring: hub face to inner obstacles, and outer lip to fender at full lock and at bump. Nothing beats a test fit, but meticulous math plus an offset calculator gets you 95% there.

Suspension and Lift Requirements

Offset and suspension lift are married. A small lift or leveling kit changes the arc tires travel through:

- More positive offset (+12 vs +1): keeps the tire tucked; sometimes avoids the need for a lift at a given tire size.

- More negative offset (−12): often demands at least a level kit to avoid liner pinch and sway-bar scuff.

- Wheel spacer effects: a 1” spacer is roughly −25 mm effective offset; treat it as such in your math. Spacers amplify hub load and can stress studs—buy hub-centric, torque correctly, and recheck after heat cycles.

If you lift, re-evaluate axle alignment and wheel alignment; added caster can help straight-line stability with wider track, reducing wander.

Potential Modifications

Sometimes your dream spec needs a little help:

- Trim & tuck: heat-gun form liners, shave a plastic seam, or relocate a bracket for tire clearance.

- Brake upgrades: big calipers need spoke shape, not just diameter. A wheel offset chart won’t show barrel bulge—ask for a template or test barrel.

- Fender liners/flares: add coverage to control spray if you end up with poke.

- Alignment & geometry: a hair more negative camber can re-center a wide tire under compression, reducing tire rubbing.

- Weight & rating: heavier wheels increase unsprung mass (wheel weight impact). Pair that with big tires and you can dull damping and stretch stopping distances. Keep an eye on load rating impact of both wheel and tire, especially on working truck wheels.

Putting +12 in Context (Practical Scenarios)

- Stock-height half-ton, 275/60R20 street tire: Moving from +24 to +12 on a 9” rim often nets a cleaner flush without liner contact, preserves handling stability, and keeps brake clearance intact.

- Mild level kit, 285/70R17 all-terrain: +12 on an 8.5” rim tucks enough inside to keep poke reasonable while clearing UCAs on many platforms. Light liner massage at the rear fender screw may be needed at full lock.

- Overland SUV, 265/70R17, big twin-piston brakes: target +12 to +20 with a barrel shape that clears the caliper bridge; offset alone won’t save you if the spoke design intrudes.

- Solid-axle Jeep on 35s: −12 is common for stance and lock-to-lock clearance on links; +12 can work with narrower tires if you value fender coverage and bearing life.

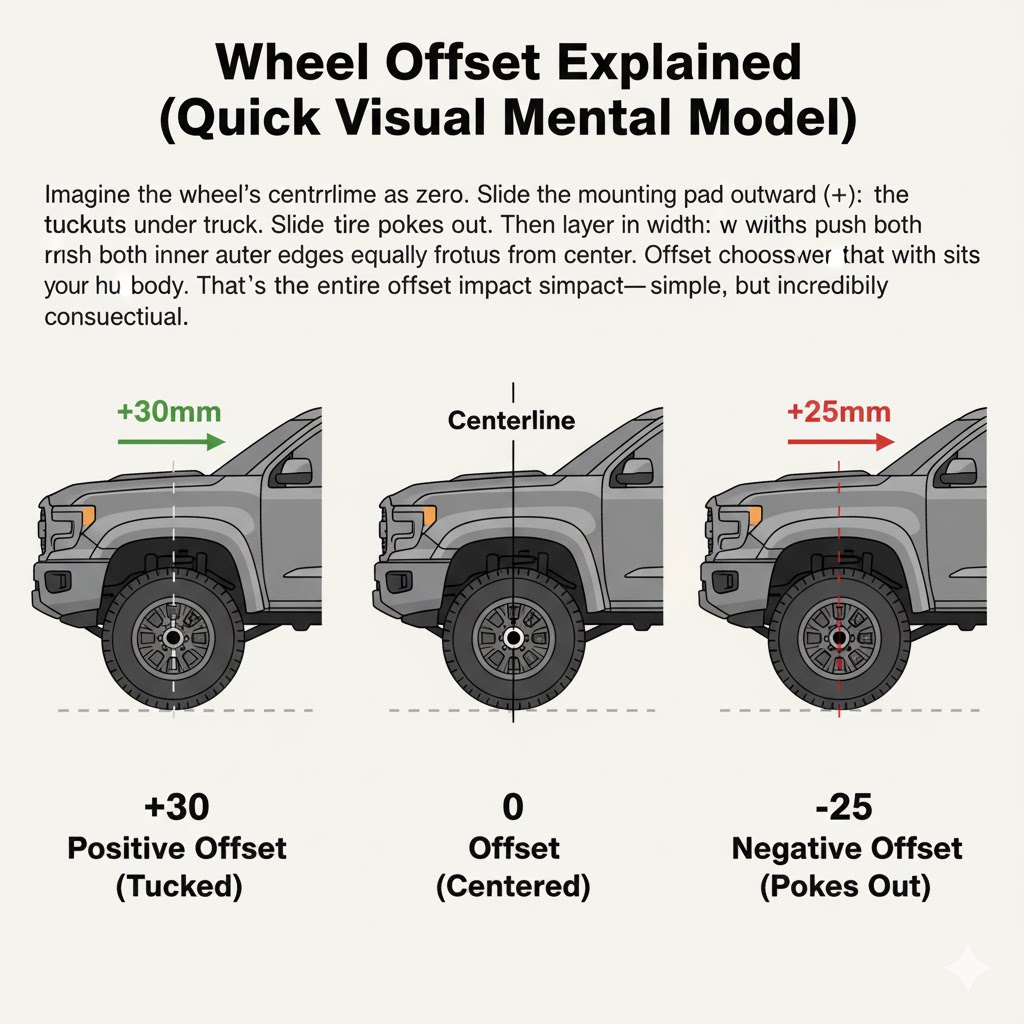

Wheel Offset Explained (Quick Visual Mental Model)

Imagine the wheel’s centerline as zero. Slide the mounting pad outward (+): the tire tucks under the truck. Slide it inward (−): the tire pokes out. Then layer in width: wider rims push both inner and outer edges equally from center. Offset chooses where that width sits relative to your hub and body. That’s the entire wheel offset impact—simple, but incredibly consequential.

Conclusion

A +12 mm offset is a sweet-spot setting for many pickups: conservative enough to protect liners and hardware, assertive enough to sharpen stance and track width a touch. Use rim width, tire size, and backspacing math to predict outcomes, then validate with a real mock-up. Check wheel clearance at full lock and full bump, confirm hub bore size, lug pattern, and center bore alignment, and don’t forget hardware basics like stud length and torque.

If you change offset meaningfully, book a post-install wheel alignment and watch for new tire wear patterns over the first thousand miles. Let looks follow geometry—not the other way around—and you’ll end up with a truck that sits right, drives right, and doesn’t chew liners or joints for breakfast.

FAQs (Offset Specifics)

How many times can I change offset before I need other mods?

Think in millimeters. A shift of ~12–20 mm from stock is usually fine on OE tires. Add width or diameter and you may need trimming or a small suspension lift.

Is +12 the same on every rim width?

No. Offset is relative to centerline. A +12 on a 9.5” rim puts the outer lip farther out than a +12 on an 8.5”. Combine wheel offset measurement with rim width to find effective backspacing.

Will +12 clear my big brakes?

Offset affects caliper clearance indirectly. What matters most is spoke shape. Always test with a template; don’t rely solely on an offset calculator.

Can spacers “fake” the right offset?

Yes—spacers reduce effective offset (more negative). But they also add leverage on bearings and studs. Use hub-centric spacers, verify stud length, and re-torque. Understand the full wheel offset effects before committing.

Do jeeps and off-road rigs want negative offset?

Many off-road vehicles and jeeps run negative offset for stance and link clearance. It works—if you accept more spray, more kickback, and potential fender rub. For daily-driven rigs, a mild positive like +12 can be a better compromise.

What about SUVs with tight arches?

Wheel offset for SUVs tends to be more positive stock. Jumping straight to +12 may demand liner work. Look at vehicle compatibility notes and test at full compression.

Will +12 change my turning radius?

Not directly, but increased tire width combined with offset can touch liners at full lock—effectively limiting turning radius until you trim or adjust steering stops.

Why does my truck wander after new wheels?

Offset, tire construction, and pressure all matter. Recheck axle alignment, camber change from any lift, and verify you didn’t upset caster. Sometimes a small toe adjustment restores calm tracking.

Leave a Reply